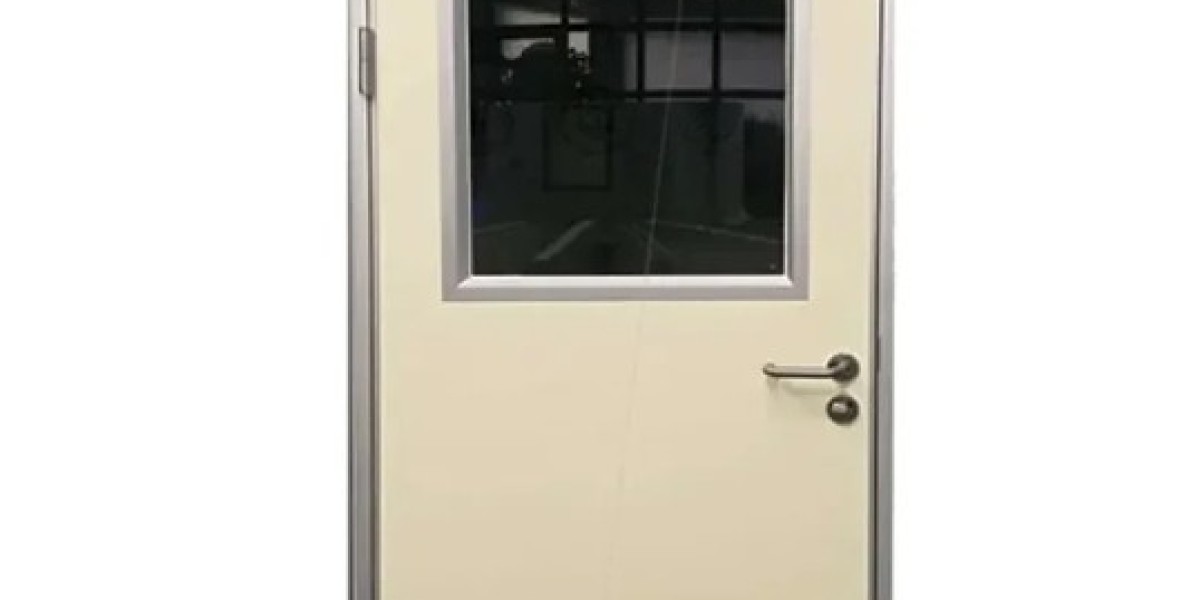

When it comes to clean room design, selecting the right door is crucial for maintaining sterility, safety, and efficiency. Medical laminated steel doors offer exceptional benefits in terms of cleanliness, durability, and customization. In this article, we will guide you through the key factors to consider when choosing the right medical laminated steel door for your clean room. GREAT Purification System, a renowned provider of clean room solutions, offers a wide range of high-quality doors that meet the stringent requirements of various industries.

I. Assessing Clean Room Requirements and Regulations

Before diving into the selection process, it's essential to assess your clean room's specific requirements and adhere to the applicable regulations:

1.1. Cleanroom Classification: Determine the clean room classification based on ISO standards or industry-specific guidelines. This classification will help you identify the level of cleanliness required and guide your door selection process.

1.2. Regulatory Compliance: Familiarize yourself with the regulatory standards governing your industry, such as Good Manufacturing Practices (GMP), FDA guidelines, or international standards. Ensure that the medical laminated steel door you choose meets these requirements.

II. Cleanliness and Contamination Control

Clean room doors play a critical role in preventing contamination and maintaining sterility. Consider the following factors related to cleanliness and contamination control:

2.1. Non-Porous Surface: Opt for medical laminated steel doors with a non-porous surface that prevents the accumulation of contaminants, such as dust, particles, and microorganisms. This feature ensures optimal cleanliness and minimizes the risk of cross-contamination.

2.2. Smooth and Easy-to-Clean Surface: Look for doors with a smooth surface that allows for effortless cleaning and disinfection. The ability to clean the door thoroughly is essential to maintain a sterile environment. GREAT Purification System's medical laminated steel doors are designed for easy cleaning and disinfection.

2.3. Sealing and Gasketing: Ensure that the door provides an effective seal when closed, preventing the ingress of contaminants. Well-designed gaskets and sealing mechanisms help maintain the integrity of the clean room and minimize particle infiltration.

III. Durability and Safety

Clean room doors are subject to frequent use and must withstand rigorous conditions. Consider the following factors related to durability and safety:

3.1. Material Quality: Choose medical laminated steel doors constructed using high-quality materials. Opting for doors from reputable manufacturers like GREAT Purification System ensures durability and longevity.

3.2. Impact Resistance: In a busy clean room environment, accidental impacts or collisions can occur. Look for doors that are designed to withstand such impacts, minimizing the risk of damage and ensuring the door's long-term performance.

3.3. Fire Resistance: Safety is of utmost importance in clean rooms. Select medical laminated steel doors that are fire-resistant. These doors can help contain fires and prevent their spread, ensuring the safety of personnel and critical processes.

IV. Customization and Compatibility

Clean rooms have unique requirements, and the door should be compatible with the overall clean room system. Consider the following factors related to customization and compatibility:

4.1. Tailored Design: Opt for medical laminated steel doors that can be customized to fit your clean room's specific requirements. Customize the size, configuration, and hardware options to seamlessly integrate the door into the clean room layout.

4.2. Compatibility with Cleanroom Systems: Ensure that the selected door is compatible with other cleanroom systems and components such as air showers, pass boxes, and interlocking systems. This compatibility ensures smooth operations and enhances the overall performance of the clean room environment.

V. Energy Efficiency and Insulation

Clean rooms often require precise temperature and humidity control. Consider the following factors related to energy efficiency and insulation:

5.1. Thermal Insulation: Look for medical laminated steel doors with excellent insulation properties. These doors help maintain stable temperatures within the clean room, reducing the energy required for temperature regulation and contributing to overall energy efficiency.

5.2. Sound Insulation: Depending on the clean room's specific requirements, noise reduction may be necessary. Consider doors that provide effective sound insulation, creating a quieter and more comfortable working environment for personnel.

Conclusion

Choosing the right medical laminated steel door is crucial for maintaining cleanliness, durability, and safety in clean room environments. By assessing your clean room requirements, considering factors such as cleanliness, durability, customization, and energy efficiency, and selecting a trusted provider like GREAT Purification System, you can ensure that your clean room door meets the highest standards. A well-chosen door will contribute to the overall efficiency, reliability, and success of your clean room operations.

Welcome to inquiry if you need to know more about Medical Laminated Steel Doors details or order wholesale.